Concrete Shelter Manufacturer

Comments Off on Concrete Shelter ManufacturerAt Module X Solutions, we specialize in designing and manufacturing concrete shelters for utility infrastructure, telecom applications, remote instrument enclosures, fiber huts, and many more modular building applications. We also offer installation and integration services for turnkey solutions. Our standard lightweight precast concrete shelters are built with exposed aggregate, but we can provide alternative exterior finishes in painted concrete, brick stencil or veneer, panel siding, cinder block, or other facade designs to match existing site architecture. Other manufacturing options we offer include fiberglass-reinforced concrete lightweight interlocking steel modular buildings or other hybrid manufacturing methodologies.

All of our engineered protective building solutions are built to comply with applicable safety and industrial regulations, including ACI 318-95, AISC, BOCA, IBC, NEC, SBC, and UBC. We also provide shelters with the structural integrity to withstand Category 5 scenarios with up to 150 mph winds. Our concrete shelters are available in single and multi-module configurations, and they can be designed to meet fire rating and ballistic requirements.

Applications for Concrete Shelters

We can design and manufacture concrete shelters for the following applications:

Concrete Telecom Shelters

Our fiberglass reinforced or lightweight reinforced concrete telecom shelters provide long-lasting service, typically lasting over 30 years with proper care. Both options provide resistance to wind, ammunition, and fire threats. Available in different size and design options including single or multi-piece layouts. Lightweight reinforced shelters are particularly ideal for remote site locations such as raw land, or mountain tops. The lightweight concrete design can save in transport and crane costs. Click here to learn more about our telecom enclosures.

Fiber Huts

Our unique and highly specialized fiber regeneration huts or colocation facilities are strategically positioned to reduce latency issues by housing and protecting equipment that quickly delivers data content. Although our standard fiber huts are constructed using concrete, we also offer metal construction options. Our specific capabilities for fiber huts include design, engineering, manufacturing, and site support services.

Remote Instrument Enclosures

Our remote shelter enclosures can house fully-integrated remote systems and motor control stations. In addition, these structures protect instruments from anything from heat to ballistics and other environmental conditions. Our enclosures can be manufactured with precast concrete, light gauge steel, or welded steel options.

Our design and engineering team can also create custom modular shelters. These concrete shelters can be single or multi-room and also come standard rated for level IV ballistic, 2 hr fire, storm, and wind resistance.

Exterior Finishes

It’s important to choose the right exterior finish based on your environment, intended application and required safety ratings. At Module X Solutions, our concrete shelters can be outfitted with the following exterior finish options:

- Brick stencil or veneer

- Customized paint options with a smooth finish

- Fluted concrete

- Hardy panel siding

- Standard exposed strained aggregate finish

Integration and Installation

Along with designing and building our unique concrete shelters and enclosures, we offer installation and integration with your existing equipment. First, we test that the shelter is fully operational and meets safety requirements before it is shipped to the installation site. We can install and integrate specialized equipment, including customer-furnished equipment (CFE), to provide a turnkey solution that is plug and play, allowing minimal site work, resulting in faster online implementation, which saves time and money in the field.

Choose Module X Solutions for Concrete Shelter Manufacturing

Choosing the right concrete shelter is an important investment in protecting on-site equipment, utilities, and remote access points. At Module X Solutions, we offer complete concrete shelter manufacturing with design, build, installation, and integration services. Contact our team today to learn more about our capabilities or request a quote to get started.

An Intro to API RP-752 and API RP-753

Comments Off on An Intro to API RP-752 and API RP-753There are no federal laws regulating what measures a facility needs to take to maintain a protected environment in the event of an explosion. However, the American Petroleum Institute (API) has established recommended practices (RP) that serve as guidelines on, among other topics, how to manage hazards associated with blast events. The two standards pertaining to blast-resistant buildings are API RP-752 and API RP-753.

The following article goes into more detail on API RP-752 and API RP-753. It outlines what they cover, how they differ, and how they discuss vapor cloud explosions (VCEs).

What Are API RP-752 and API RP-753?

Established in 1919, the American Petroleum Institute is a trade association that represents all facets of the natural gas and oil industry. They promote safety and weigh in on public policy within the United States. Among their vast collection of RPs are API RP-752 and API RP-753. These standards outline procedures for permanent and portable buildings that focus on ensuring personnel are as safe as reasonably possible from fires, explosions, and the potential release of toxic hazards.

- API RP-752 was first released in 1995. It covers how to manage hazards associated with permanent structures in fixed locations. It was originally developed for use at natural gas liquids extraction and liquefaction plants, petrochemical and chemical plants, refineries, and other onshore facilities covered by the OSHA Process Safety Management of Highly Hazardous Chemicals, 29 CFR 1910.119.

- API RP-753 was first released in 2007. It covers how to manage hazards associated with portable buildings that are conventionally not constructed for blast or fire resistance.

Some of the topics covered within these standards include:

- Personnel regulations: Personnel should be located away covered process areas when possible.

- Occupied buildings: Buildings are considered occupied if they have assigned personnel or regularly have personnel come to them. They should be designed, constructed, installed, and maintained to protect occupants against possible hazards. Additionally, the use of occupied buildings close to covered process areas should be minimized, especially during periods of increased risk (e.g., unit start-up or planned shutdown operations).

- Existing buildings: Existing buildings that fail to meet the criteria should have a proper mitigation plan documented and implemented for any issues uncovered during an evaluation for as long as they are in use.

How Are API RP-752 and API RP-753 Different?

API RP-752 and API RP-752 are highly similar. They are both meant to protect personnel against the same potential hazards—i.e., explosions, fires, and toxic contamination. The key difference between them is the type of building they cover. API RP-752 focuses on permanent buildings, while API RP-753 focuses on portable buildings.

How Do API RP-752 and API RP-753 Cover VCE?

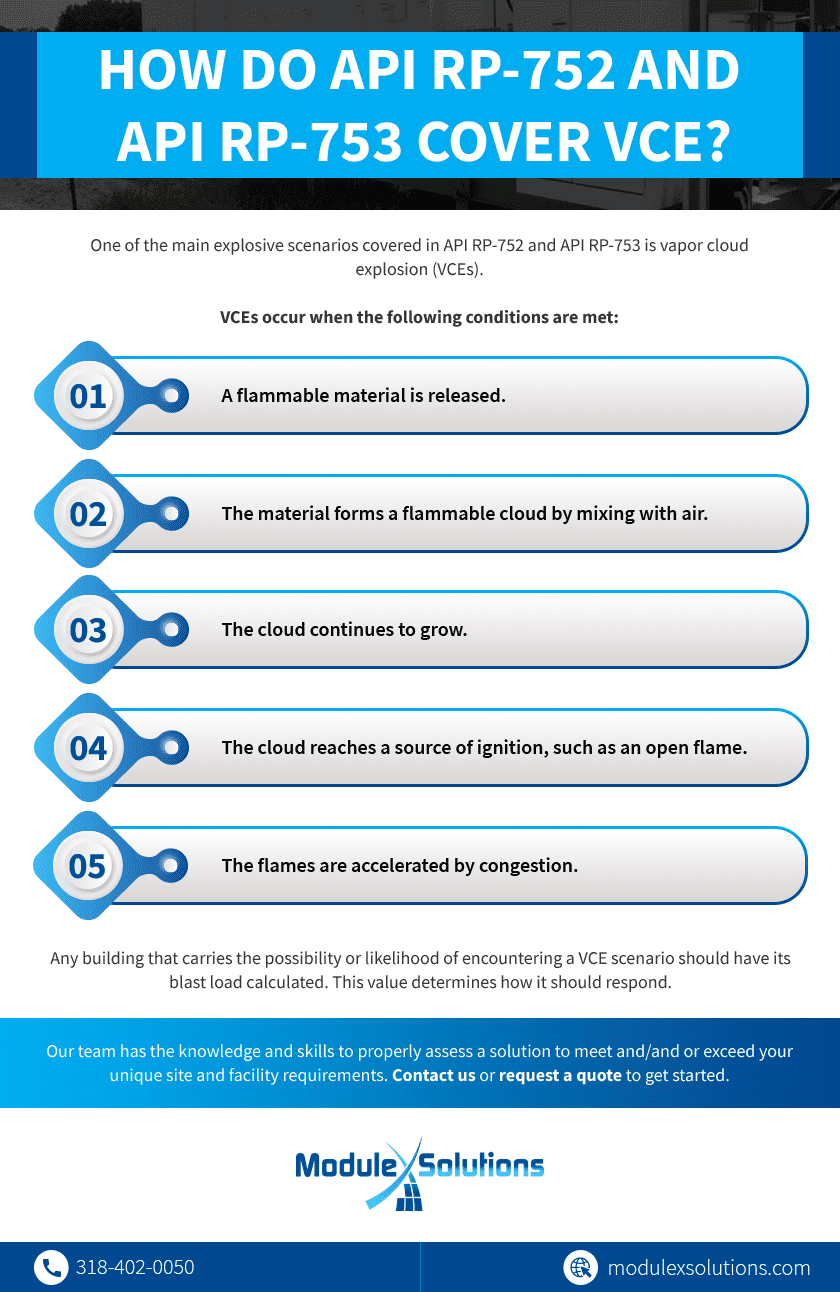

One of the main explosive scenarios covered in API RP-752 and API RP-752 is vapor cloud explosion (VCEs). VCEs occur when the following conditions are met:

- A flammable material is released.

- The material forms a flammable cloud by mixing with air.

- The cloud continues to grow.

- The cloud reaches a source of ignition, such as an open flame.

- The flames are accelerated by congestion.

Any building that carries the possibility or likelihood of encountering a VCE scenario should have its blast load calculated. This value determines how it should respond.

Schedule Your Facility Planning Consultation With Module X Solutions Today

While API RP-752 and API RP-753 provide general guidelines on how to keep personnel safe from explosions, fires, and toxic materials in permanent and portable buildings. Your facility siting info can assist to support and develop a more targeted approach. The results of the evaluation and requirements can uncover any problem areas where personnel safety is at risk, allowing facility owners or operators to implement appropriate solutions before an accident can occur. Module X Solutions can further assist in guiding and ensuring you’re on the right path by taking all factors into consideration for an optimal streamlined solution.

Interested in learning about an optimal building design? The experts at MXS are here to help! Equipped with extensive experience designing and manufacturing blast-resistant buildings, our engineering team has the knowledge and skills to properly assess a solution to meet and/and or exceed your unique site and facility requirements. Contact us or request a quote to get started.